Mokume Gane is a Japanese term that

roughly translates to mean “wood-grain in metal”. It was always

one of those ancient mysteries of the orient. Primarily it was a

metal billet formed from layers of metals that varied greatly in

color. These billets were then shaped and deformed to bring out

brilliant patterns on the surface. This metal technique was seen

mostly in the furnishings of samurai swords. These uses included

handles, guards and the sheaths of these weapons. Mokume Gane was

highly secretive process that was passed on from artisan to artisan

in an oral tradition.

The process of forming these multilayer

billets predated technology and as such the process was controlled

and duplicated by religious constraints. The temperatures were often

regulated by the colors of a rising sun and the timing by the length

of a chant or song. Oral traditions are easily broken as the number

of participants dwindle. By the beginning of the twentieth century

the secrets of Mokume Gane were thought to have passed beyond recall.

Fast forward to the rise of “Metal

Arts” in American colleges and Art schools during the late sixties

and early seventies. During this time period there was a wide

spread attempt to reproduce the look of Mokume Gane using modern

techniques. Many artisans used layers of different colored metals

soldered together with silver solder to mimic the ancient art form.

The results these efforts produced were very limiting, superficial

and mostly unsatisfactory. There were wide spread rumors in the

metal art world of individuals that wanted to make excursions into

the orient to interview the old artisans of the knife guilds to try

to glean some of the old ways. It was a hope that this information

might result in a translation of the old oral tradition into modern

metallurgy. It is not the scope of this article to explore who went

where and discovered what. It is a fact however, that today one can

obtain information that will result in a very satisfactory Mokume

Gane billet regardless of how close it adheres to the materials of

the seventeenth century. I bring your attention to the materials,

publications, classes and lectures of such metal artists as Steve Midgett, James Binnion and the metal wizard I have watched closely,

Phillip Baldwin.

Speaking of “Phillips” my client

Philip wanted us to make a cuff for him that would turn heads and

start conversations. He wanted something classy but still with a lot

of eye appeal. I thought that Mokume Gane would be just the thing.

I have always admired subtle things like fine Irish linen, where the

closer you look the more there is to see. Sometimes you have to just

sit back and let the material do the talking.

The cuff form itself was shaped in a

hydraulic press with tooling that I made myself using magnets and

mild steel. There was a lot of experimenting using copper and brass

blanks to get the shapes and lengths just right. It was more than

once I nearly gave my finger a good pinch in the press. But after a

bit of time, some patience and a bunch of tweaking the project

started to come around. My hydraulic press is an old “Bonny Doon”

from years ago. We don't use it as much as we should and sometimes

we even forget that it's in that far dark corner of the studio just

under the breaker panel.

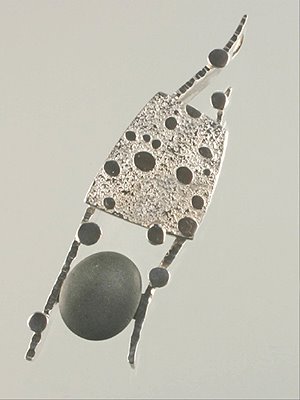

My plan was to keep this piece fairly

simple and rely on the materials and “glyph” to do the heavy

lifting. This is the Mokume Gane cuff that I made for him with the ever

present band “glyph” on top.